|

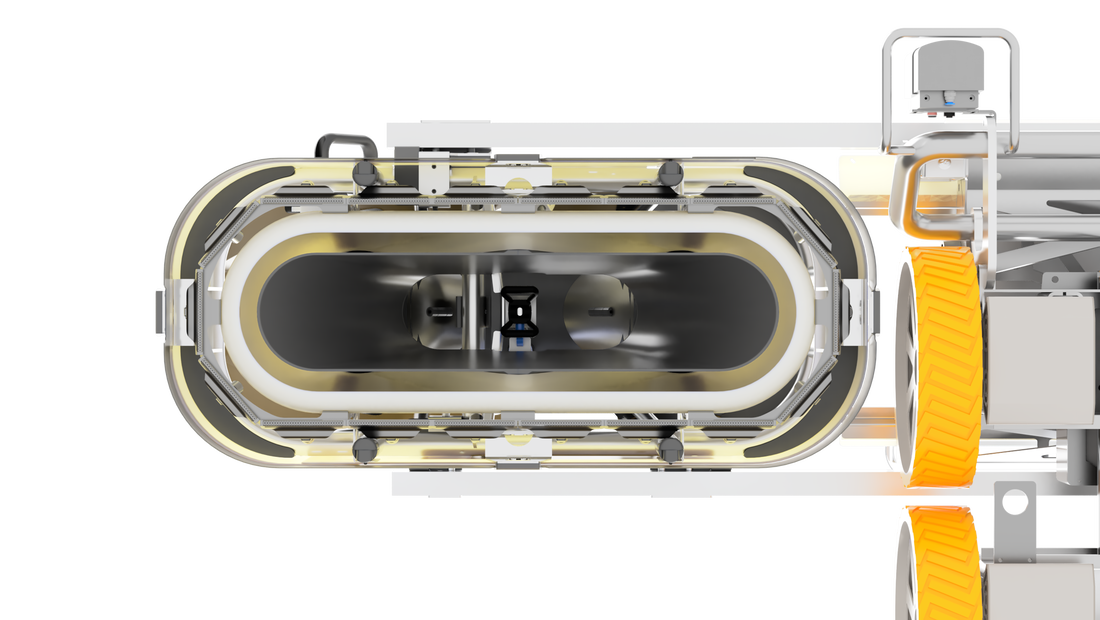

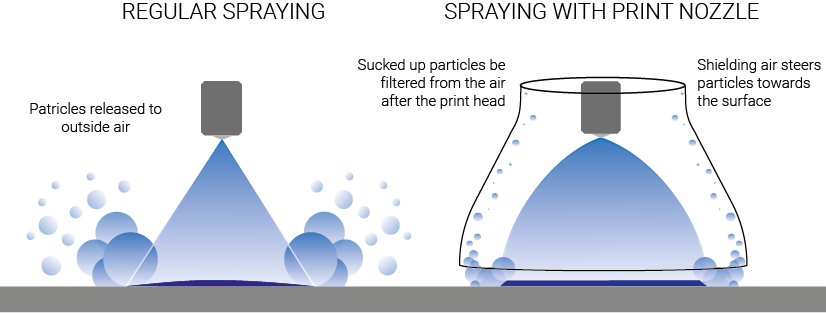

Maximizing accuracy and efficiency Qlayers’ advanced technology enables clients to have full control over every aspect of the automated painting process by applying accurate layers, reporting data about layer thicknesses, temperature, humidity, and automated quality control on every position of the tank. |

Our technology enables coating companies to deliver better and faster work onsite, while keeping their personnel safe. Learn more about our automated coating solutions: