Since its commercialization in 2022, customers worldwide have adopted the 10Q coating robot mainly because of its significant advantages. And now, you can also experience the same benefits at very competitive rates, starting at 0,77 €/m2.

The Qlayers’ 10Q robot is approved by many asset owners and works with all paint manufactures.

People working on unsafe heights from suspended platforms

Inconsistent speed of 30 m2/h (323 ft2/h) from coating manually using scaffolding

Manual quality control, measuring layer thickness only on a few points

Manual coating application is inconsistent, also within quality control standards

Up to 80% less working hours at dangerous heights

Consistent speed of up to 200 m2/h (2150 ft2/h) per 10Q robot

Automated quality control on every coated area of the tank, reporting data about layer thicknesses, temperature, humidity, etc.

Environmentally friendly coating process due to overspray minimization

In response to significant market demand, Qlayers has established Qlayers Rental B.V. to offer a new rental program, providing flexibility and convenience for asset owners and contractors involved in coating large surfaces such as storage tanks and ships.

The rental program includes comprehensive training for your existing workforce to ensure seamless integration and optimal performance of the 10Q coating robot. Additionally, experienced operators, supervisors, and system experts are available to guarantee that the system is implemented and used to its full potential, delivering the best possible results.

With competitive weekly rates starting at 2.50 €/m2, the 10Q robot offers a cost-effective alternative to traditional methods, enhancing safety, sustainability, and productivity. By integrating this advanced technology, your business can achieve improved efficiency and competitiveness.

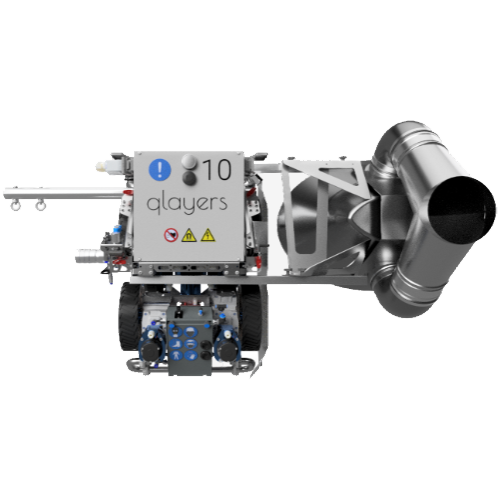

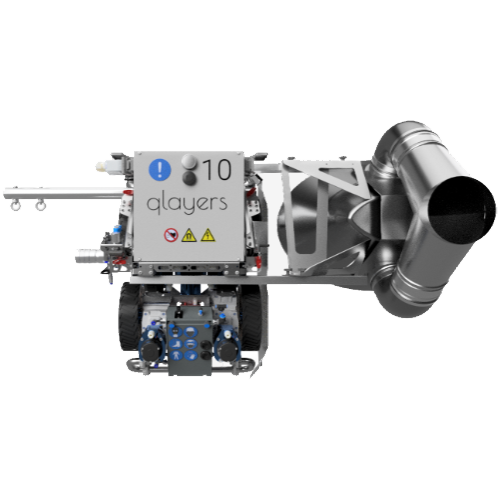

Qlayers’ patented spray shielding system

A unique feature of the robots that allows to coat surfaces with high precision, accurate layer thickness and high transfer efficiency (up to 90%).

The shielding system is designed to extract the minuscule paint spray that isn’t transferred to the surface and prevents it from being released into the environment.

Back to overview

Magnetic Crawler with Remote Control

The crawler serves as a foundation to move the spray shielding system along the surface, and is held in place onto the asset’s exterior surface using magnets. It is secured with a fall arrestor as a safety measure.

With our patented spray shielding system, advanced sensors, and control technology, the crawler excels in:

The operator can drive the magnetic crawler safely from the ground using an intuitive user-friendly remote control, reducing 80% of working hours at dangerous heights.

Back to overview

The trailer acts as a powerhouse, providing power, air and paint supply for the crawler to coat.

In addition, the trailer is also integrated with:

We recently established our novel rental business for project-based attainment of robots available within the EU. For other regions, the availability to rent depends on the respective distributor. We are happy to provide further details on request.

At the start of a project, it takes about two hours to set up the tank brackets/support system, do a test drive, and prepare the painting system. It takes another two hours to break down the system and clean the paint system at the end of a project.

Once the robot is set up, it takes only 15 – 30 minutes each day to start the system and another 15 – 30 minutes to flush at the end of a shift.

The current hood can cover about 200 m² without cleaning, which takes 5 minutes. A filter change might also be needed depending on filter size and paint particles. Subject to the object’s layout and dimensions, breaks to move the crawler past obstacles and reposition the trailer might be required.

For the rest, you can continue the coating application process without breaks. It is important to note that the robot is semi-automatic; thus, robot operators need to be present at all times.

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged.

The average coating speed is 200 m²/h. Primers and intermediates are usually applied at greater layer thicknesses than topcoats, potentially leading to slower driving (±180 m²/h) than for topcoats (±220 m²/h).

Eventually, the coating speed depends on vertical lane length. Longer lanes allow for higher coating speed and less disruption through lane switches. The lane length is influenced by the tank/vessel height and obstacles such as wind girders and stairs.

The whole system is CE-certified, and the pump is ATEX-certified. Additionally, the system has multiple emergency stop buttons (on the trailer and remote control), and a gas sensor shuts it down entirely if the level exceeds 10% of the LEL.

The crawler is attached to the surface with four permanent magnets, making it fail-proof against an electrical outage. A fall arrest system serves as a backup in the unlikely event the crawler detaches from the wall.

Since the product launch in 2021, our 10Q robot has been successfully deployed in a variety of projects. For details on the availability, please reach out via our contact page.