BRINGING THE LAB PRECISION TO THE INDUSTRIAL SETTINGS

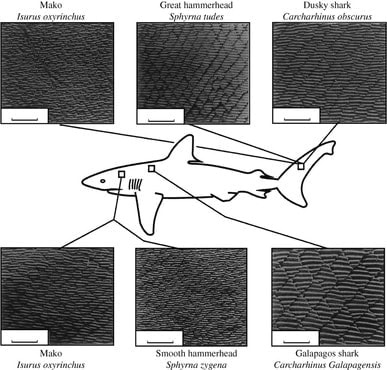

Qlayers' R&D team has done extensive research on precision coating and printing the microstructures on large industrial surfaces to make them multi-functional. Inspired by nature and fascinating riblets in the skin of sharks that reduce the drag with water, our team is aiming to develop an innovative technology to print microstructures in the scale of micrometres that can start a revolution in industries such as aviation and wind energy.

Qlayers' R&D team has done extensive research on precision coating and printing the microstructures on large industrial surfaces to make them multi-functional. Inspired by nature and fascinating riblets in the skin of sharks that reduce the drag with water, our team is aiming to develop an innovative technology to print microstructures in the scale of micrometres that can start a revolution in industries such as aviation and wind energy.

For example, printing sharkskin microstructures on the surface of wind turbine blades can reduce the frictional drag with air and drastically increase their yield by 5%. In the aviation industry, smartly coated airplane wings can hugely reduce the fuel consumption and CO2 emissions of aircraft.

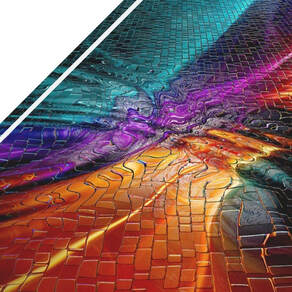

SHARKSKIN RIBLETS

Qlayers invented a technology to print microstructures on surfaces. Over the last decades, it has been shown by researchers that in nature all surfaces are multifunctional. An example is a shark, which has microstructures on it's skin that reduce drag with water. Researchers have been replicating these structures in the lab for many years. However, it was always a challenge to apply the structures on a larger scale. We developed a patent pending technique which has the potential to make this happen.

Reducing drag with sharkskin

|

It has been proven that the microstructures that you can find on a shark' skin reduce friction drag in water or air up to 8%.

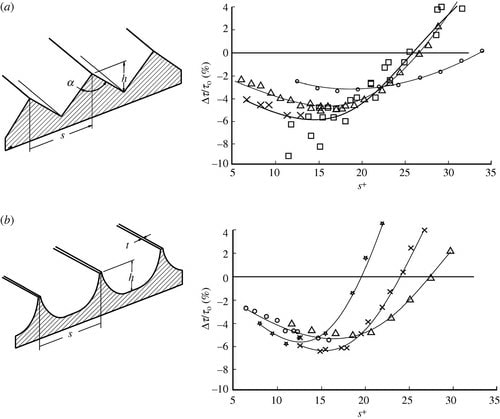

This principle has been known for over 50 years. For example, a sharkskin coating was applied to the sailboat Stars and Stripes, winning the America's Cup in 1987. Since then, structured coatings have also been applied to swimsuits and aircraft, to increase top speed or reduce fuel consumption. Qlayers believes that costly application methods and ease of fouling have prevented widespread application on aircraft, ships and wind turbines. To solve these problems and to make functional surfaces reality, Qlayers developed a new application method with which sharkskin structures can be printed in a cost efficient and fast way. We use the existing theory around sharkskin structures. The only thing that we change is the application method. On the right you see some results of over 30 years of research on the drag reduction of sawtooth (a) and scalloped riblets (b). The reduction Δτ/τ₀ depends on the non-dimensional riblet spacing s+. For yachts, the optimal spacing is between 50 and 100 μm. |

We love the planet!

Take a look at our sustainability vision.

|

MAKING EACH SURFACE FUNCTIONAL

Nature is full of functional coatings, from penguins to sharks, from anti freezing to drag reducing, each surface is functional. To apply functional microstructured coatings on industrial surfaces, Qlayers has developed a special printing technique. The controlled environment allows Qlayers to apply innovative functional coatings. Coatings can offer more than color and protection. They have the potential to radically improve fuel consumption, reduce CO₂ emissions, avoid expensive methods for de-icing and assist maintenance in the energy and transportation sector.

|

The first version of our automated coating head is already transforming the way in which coatings are applied and currently we are evolving our system into new versions to solve different market needs.

|

|